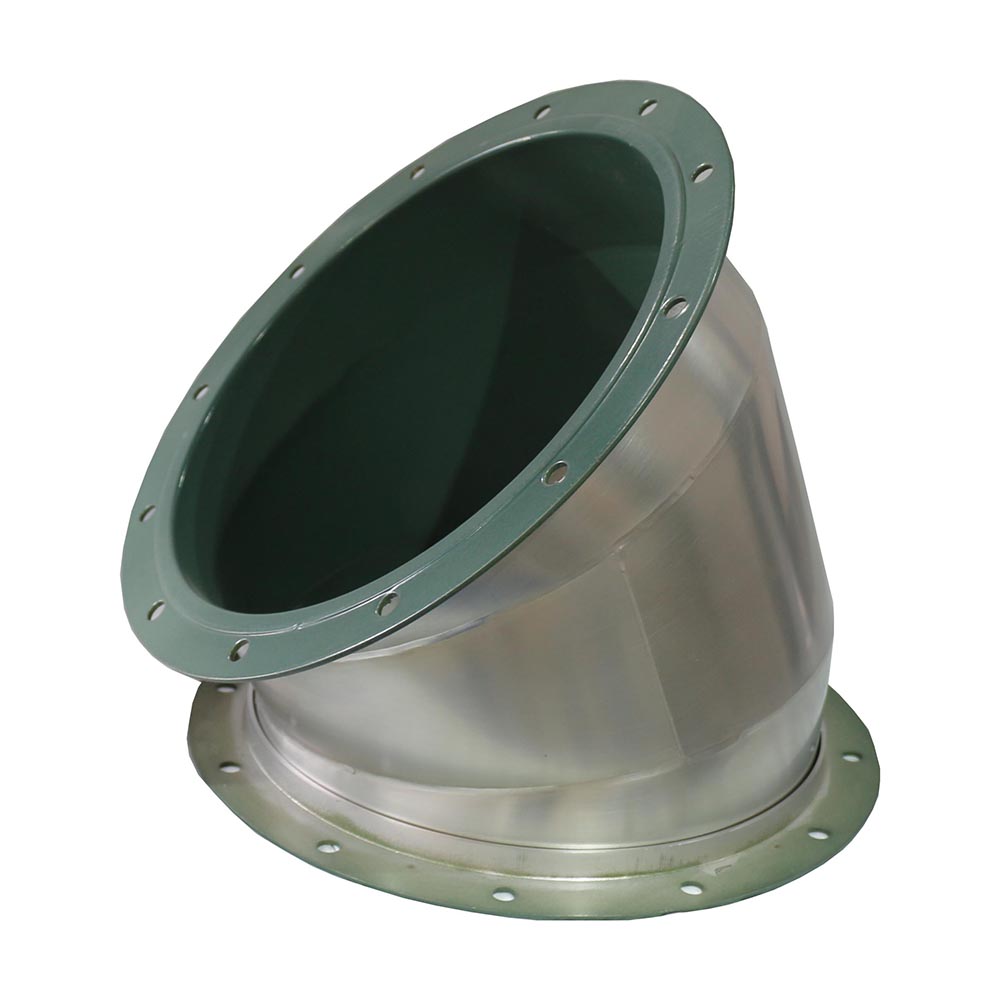

SUS304/ Dahaarka Teflon 45° xusul (3 Gore)

| Qodobka No. | Dhexroorka (mm) | Degree | Radius (mm) | gore (PC.) | Dhumucda (mm) |

| E45-0250 | 250 |

|

|

| 0.8 (ama codsiga macaamiisha) |

| E45-0300 | 300 |

|

|

| 0.8 (ama codsiga macaamiisha) |

| E45-0350 | 350 |

|

|

| 0.8 (ama codsiga macaamiisha) |

| E45-0400 | 400 |

|

|

| 1.0 (ama codsiga macmiilka) |

| E45-0450 | 450 |

|

|

| 1.0 (ama codsiga macmiilka) |

| E45-0500 | 500 |

|

|

| 1.0 (codsiga macaamiisha) |

| E45-0550 | 550 |

|

|

| 1.0 (ama codsiga macmiilka) |

| E45-0600 | 600 |

|

|

| 1.0 (ama codsiga macmiilka) |

| E45-0650 | 650 |

|

|

| 1.0 (ama codsiga macmiilka) |

| E45-0700 | 700 |

|

|

| 1.2 (ama codsiga macmiilka) |

| E45-0750 | 750 |

|

|

| 1.2 (ama codsiga macmiilka) |

| E45-0800 | 800 |

|

|

| 1.2 (ama codsiga macmiilka) |

| E45-0850 | 850 |

| R=0)l |

| 1.2 (ama codsiga macmiilka) |

| E45-0900 | 900 | 45° | or | 3pcs. | 1.2 (ama codsiga macmiilka) |

| E45-0950 | 950 |

| R=1.5x01 |

| 1.2 (ama codsiga macmiilka) |

| E45-1000 | 1000 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1100 | 1100 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1200 | 1200 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1300 | 1300 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1400 | 1400 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1500 | 1500 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1600 | 1600 |

|

|

| 1.5 (ama codsiga macmiilka) |

| E45-1700 | 1700 |

|

|

| 2.0 (ama codsiga macmiilka) |

| E45-1800 | 1800 |

|

|

| 2.0 (ama codsiga macmiilka) |

| E45-1900 | 1900kii |

|

|

| 2.0 (ama codsiga macmiilka) |

| E45-2000 | 2000 |

|

|

| 2.0 (ama codsiga macmiilka) |

| E45-2500 | 2500 |

|

|

| 2.5 (ama codsiga macaamiisha) |

Fiiro gaar ah:

1. Dhexroor ka badan 2000mm waa la heli karaa haddii la codsado.

2. Dhumucdiisuna waxay ku dhisan tahay SMACNA "heerarka dhismaha dhuumaha warshadaha wareega0fasalada 1 iyo 5 ee cadaadiska -2500Pa (-10 in.wg) .Iyo sidoo kale waxaa loo bedeli karaa codsiga macmiilka.

1. U soo jiid qalabka tuubada qolka dahaarka, bilow rinjiyeynta, ku buufi mashiinka daahan budada ah ee elektrostatic iyo tuubada qoriga buufinta fidsan, u hagaaji waqtiga sinta si dhexdhexaad ah iyadoo loo eegayo sifooyinka alaabta ceeriin ee 15 ~ 20 daqiiqo, iyo heerkulka sintering waa. 285°~300°C.

2.100% wadarta guud ee kormeerka tayada (ogaanshaha dhumucda filimka, ogaanshaha pinhole), oo leh tijaabiyaha dhumucda filimka si loo ogaado dhumucda filimka.Dhumucda filimku waa 260 ± 30 μm.Baaraha pinhole ayaa loo isticmaalaa in lagu ogaado in dahaarka uu leeyahay godad godad leh iyo in kale.Ku hagaaji tamarta ogaanshaha caadiga ah 2.5KV, haddii ay jiraan irbado u baahan in la hagaajiyo ama dib loo sameeyo.Dhumucda filimka iyo natiijooyinka baaritaanka pinhole ka dib kormeerka tayada waa in lagu diiwaangeliyaa "Foomka Kormeerka Tayada Duct Coatung".

3. Ka dib marka la dhammeeyo qaybta shaqada, bannaanka tuubada waxaa lagu dhejiyaa sumadda caddaynta FM, lambarka taxan ee QC iyo calaamadda qeexitaanka alaabta.Afka flange waxaa lagu xidhay saxan PE ama looxa jiingadaha bannaan ee PP, waxaana lagu hagaajiyay cajalad tuubo caag ah.

Dhexroorka 4.Duct ka badan 2000mm ayaa la heli karaa marka la codsado.Dhumucdiisuna waxay ku dhisan tahay SMACNA.Waxaana sidoo kale loo bedeli karaa codsi macmiil ahaan.